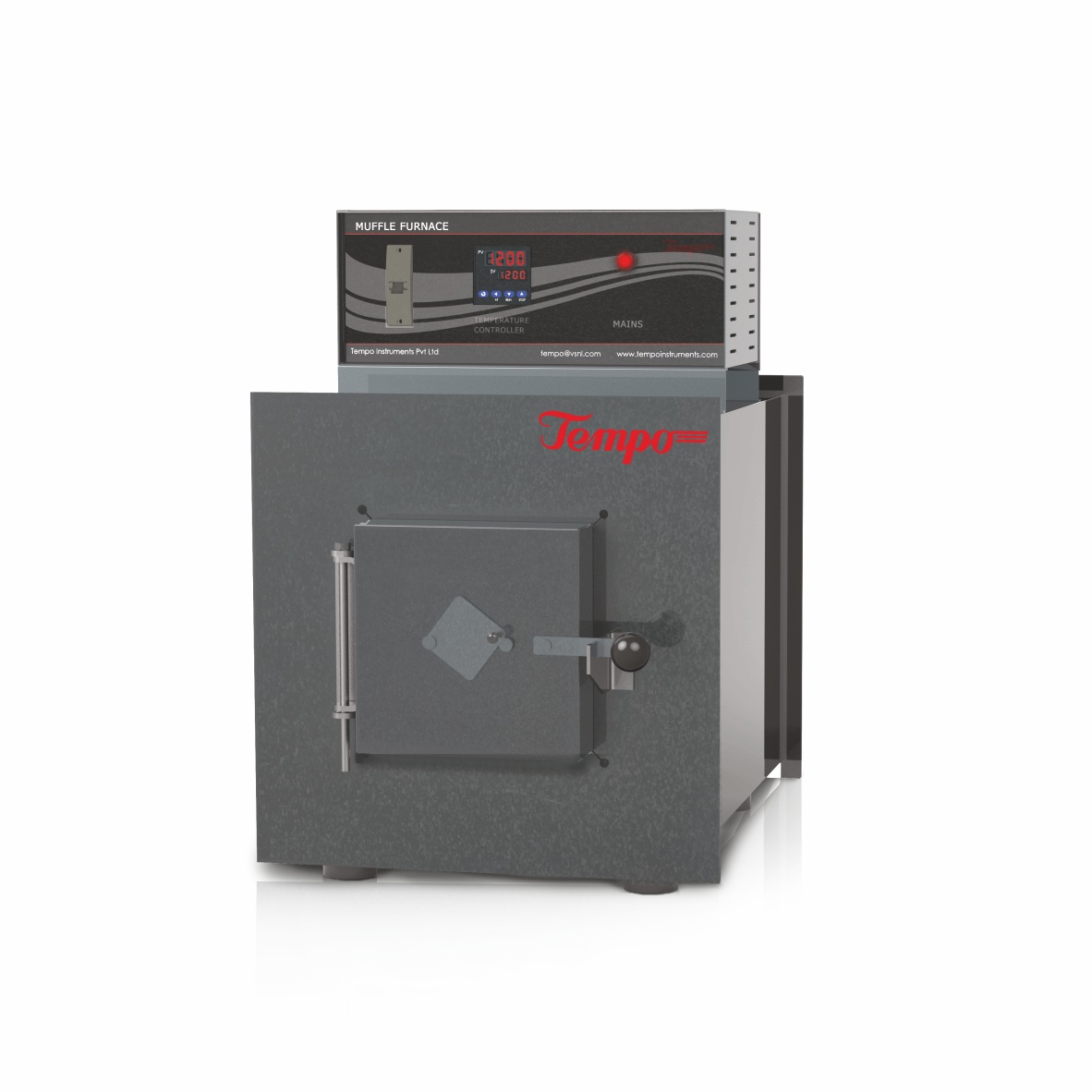

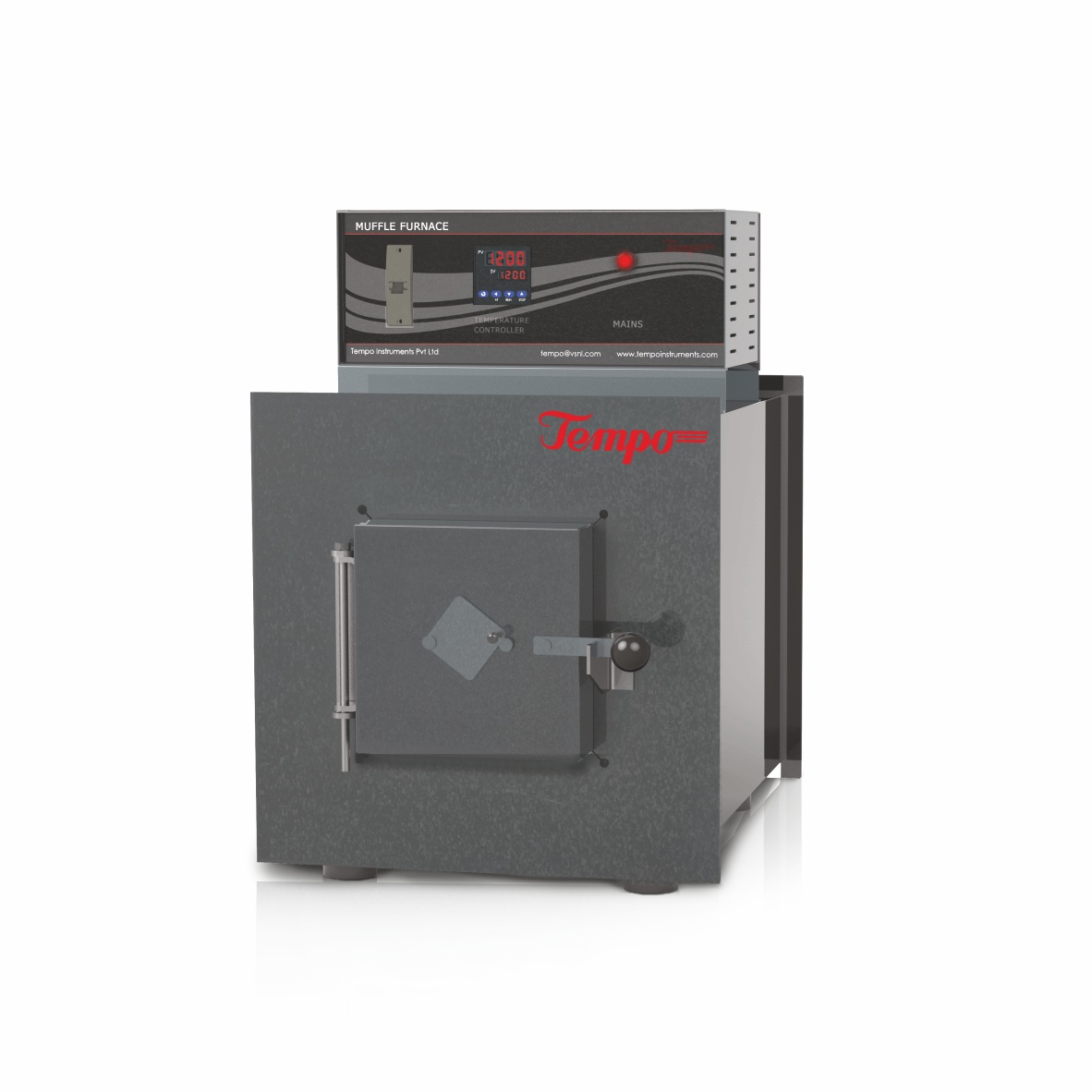

Laboratory Muffle Furnace 1700°C

₹

Furnace design with powerful heating elements i.e. FeCrAl, SiC and MoSi2 on both sides providing a fast heating rate.

Top Syringe Compound, W.E. Highway, Pandurang Wadi, Behind Samarat Hotel, Mira Road, Gate No.126

Product Description

Application

Muffle Furnace is designed for R&D labs, Educational institutions , Medicine and Industry, Chemical Industries, Plastic Industry, Moulding Industry, Glass Industry, Rubber Industry, Ceramics Industry, Biomedical Industry, Paint Industry, Textile Materials, Pharma Industry, Dental Labs, Thermal Process Technology, Advanced Materials for following applications, Testing, Analysing, Ashing, Drying, Sintering, Annealing, Melting, Tempering, Hardening, Dental Porcelain, and Crystalizing etc.

- Temperature range – 1700°C max

- Supply – Single phase/three phase

Features

- Maximum operating temperature range up to 1700°C.

- Dimensions from 1 up to 200 litres.

- Rugged and durable construction.

- The outer casing is made up of thick mild steel with duly powder coated or thick buffed stainless steel, gives long service life with

extremely resistant. - Multiplayer insulation with vacuum formed ceramic fibre or refractory bricks with low thermal mass.

- Parallel guided swing aside door design.

- Furnace design with powerful heating elements i.e. FeCrAl, SiC and MoSi2 on both sides providing a fast heating rate.

- Fast heat up and cool down rates.

- Temperature uniformity +/- 5°C.

- Temperature control with PID controllers.

- Power control with solid-state relays or Thyristor units for very precise temperature Control, wear-free and noiseless.

- High mechanical durability, short heating cycle and low power consumption.

Optional Features

- Over Temperature/Over Current Limiter

- Touchscreen temperature controller

- Port for additional thermocouple.

- Process observation window.

- Chimney for forced air extraction.

- Additional ceramic/SiC bottom plate.

- Buzzer, Digital timer, Emergency shut down.

- Data Recorder.

- RS232/RS485/USB interface.

- Calibration of temperature measurement systems.

- Gas purging facility Table for supporting the systems.

- Data Acquisition System (DAS) through software.

- UPS Systems.

- Customization as per user requirement.

- Caster wheels with brakes.

- Door safety switch.

Models & Optional Features

Models Rating (kW) Internal Dimensions

H × W × D (cm)

Supply TI – 63 HTA 4.5 10 × 10 × 23 1 ph, N, 230V, 50Hz TI – 63 HTB 5.1 15 × 15 × 30 3 ph, N, 440V, 50Hz TI – 63 HTC 5.5 20 × 20 × 30 3 ph, N, 440V, 50Hz TI – 63 HTD 10.7 22.5 × 22.5 × 45 3 ph, N, 440V, 50Hz

Hospital & Diagnostics

Hospital & Diagnostics Industrial Supplies

Industrial Supplies Electronics & Electrical

Electronics & Electrical Food & Beverages

Food & Beverages Industrial Plants & Machinery

Industrial Plants & Machinery Building & Construction

Building & Construction Apparel & Garments

Apparel & Garments Packaging Machines & Goods

Packaging Machines & Goods Chemicals, Dyes & Solvents

Chemicals, Dyes & Solvents Mechanical Parts & Spares

Mechanical Parts & Spares

View Mobile

View Mobile